Fresh cassava tubers, especially the high-quality ones, are very perishable. They begin to spoil within 2-3 days after harvest; therefore must be dealt with quickly.

The process of creating dried cassava slices

Cassava tubers used in the production of industrial animal feed are sliced and dried, then often mashed or pressed. The choice of treatment technology depends on the number of cassava to be processed, the availability of raw materials and labor costs, as well as the locally available inexpensive energy sources.

The first step is washing, followed by peeling. Cassava tubers are sliced by hand or by machine. Cassava slices can have different sizes and shapes, rectangles, cubes, and thicknesses depending on the cutting and drying method. Cassava can be dried naturally or artificially. The process of drying cassava is done on concrete floors or trays. Drying in the sun is a labor-intensive method, requiring about 35-40 workers/ha of drying the floor. Cassava slices dried on a tray look better and dry more evenly than drying on a concrete floor. The artificial drying method is carried out by stationary or mobile dryers, or rotating dryers. Cassava slices can be sold directly, ground into flour, or pressed into cakes.

T-Global manufacture high-quality Dried Cassava Slices from Viet Nam

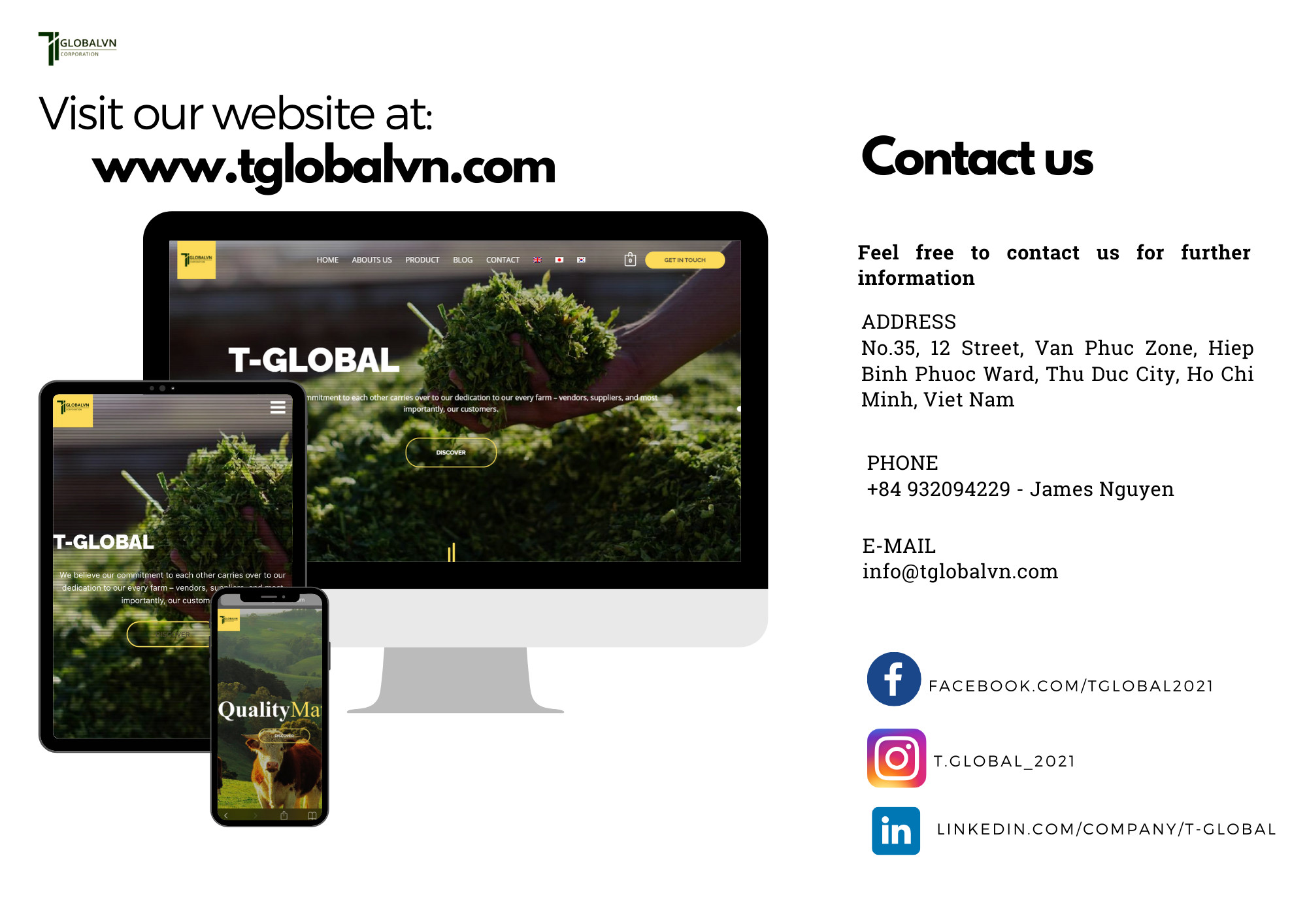

Visit us: https://tglobalvn.com