Sugarcane bagasse derived from agricultural residues, in general, may be used in the manufacturing in many factories, as they minimize environmental impact and are natural substitutes for wood to heat with producing a large amount of energy.

1. Sugarcane bagasse pellet can produce large energy

Nowadays, many factories or power plants required a great deal of energy from heating. Therefore, in developed countries such as the US, Japan, Korea, etc., power plants often use the sugarcane bagasse pellets to be able to obtain high temperature in producing process. One more benefit of using sugarcane bagasse pellet is to reduce emissions into the environment.

2. The process of making sugarcane bagasse pellet

There are 7 steps in this process:

1. Raw materials: Collect sugarcane bagasse after the process of making sugar from fresh sugarcane.

2. Drying: Sugarcane bagasse should be dried to dehydrate.

3. Raw mash: Mash the sugarcane bagasse in a raw way.

4. Advance mash: Mash the sugarcane bagasse carefully to produce smoother flour.

5. Press the pellet: Start making sugarcane bagasse pellet by pressing them.

6. Dust sieve and cool down: Before packing sugarcane bagasse pellet into bags, we need to sieve the dust from pellet making process and cool the products.

7. Packing: Pack the products into bags and be ready to serve.

T-Global manufacture high-quality Sugarcane Bagasse Pellet from Viet Nam.

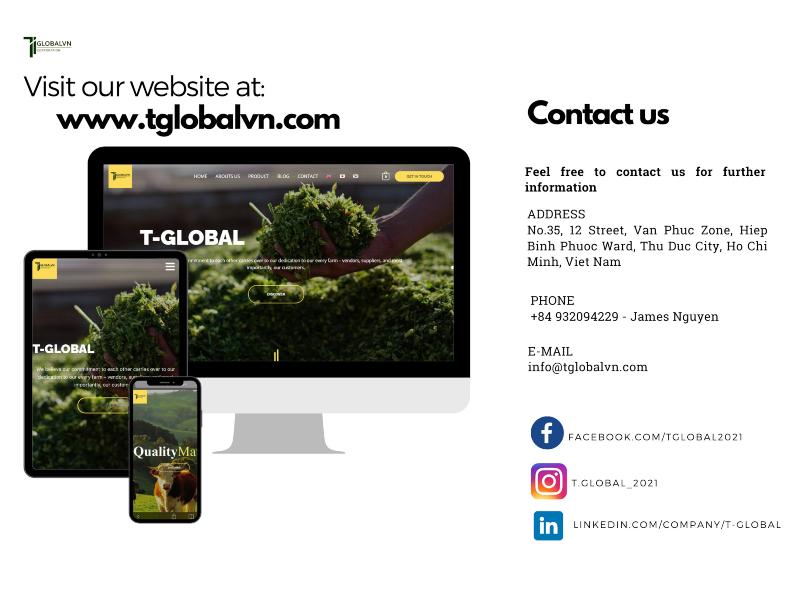

Visit us: www.tglobalvn.com