Cassava bagasse, which is a fibrous material, is the by-product of the cassava-processing industry. It contains about 30–50% starch on a dry weight basis. Due to its rich organic nature and low ash content, it can serve as an ideal substrate for microbial processes for the production of value-added products.

For chicken

In well-coordinated formulations, high-quality cassava chips can be used at a high level in broilers without any loss of performance (Chauynarong et al., 2009, Daghir, 2008). For example, supplementing with 50% cassava pellets resulted in comparable results with that of corn supplementation (Stevenson et al., 1983). With the addition of more than 30% of the unshelled tapioca starch in the feed, some authors showed a decrease in feed intake, a negligible decrease in growth, but still maintaining a feed efficiency. (Mafouo Ngandjou et al., 2011). Finely mashed tapioca (<1mm) may reduce performance compared to raw yams (Mafouo Ngandjou et al., 2010). The amount of feed consumed in chicks may be affected when the fortified cassava content is high (50%), while the older chickens maintain the performance (Brum et al., 1990). Initial reports of decreased growth with cassava supplementation may be due to high HCN concentrations or protein/amino acid deficiencies (Chauynarong et al., 2009).

Although there is no specific limit to the amount of high-quality cassava added to the fattening-chicken pellet diet, since tapioca is low in protein, the amount of fortification should be at 30. - 40% to meet other needs in the ration. When chicken feed is in powder form, the addition of cassava should not exceed 20-30%, especially for chicks (Buitrago et al., 2002a). Other lower quality tapioca products, for example, dust-free, unshelled, or tapioca with high HCN content without control or restriction on quality control, should be used with greater care and The rate of use should not exceed 20% of the diet.

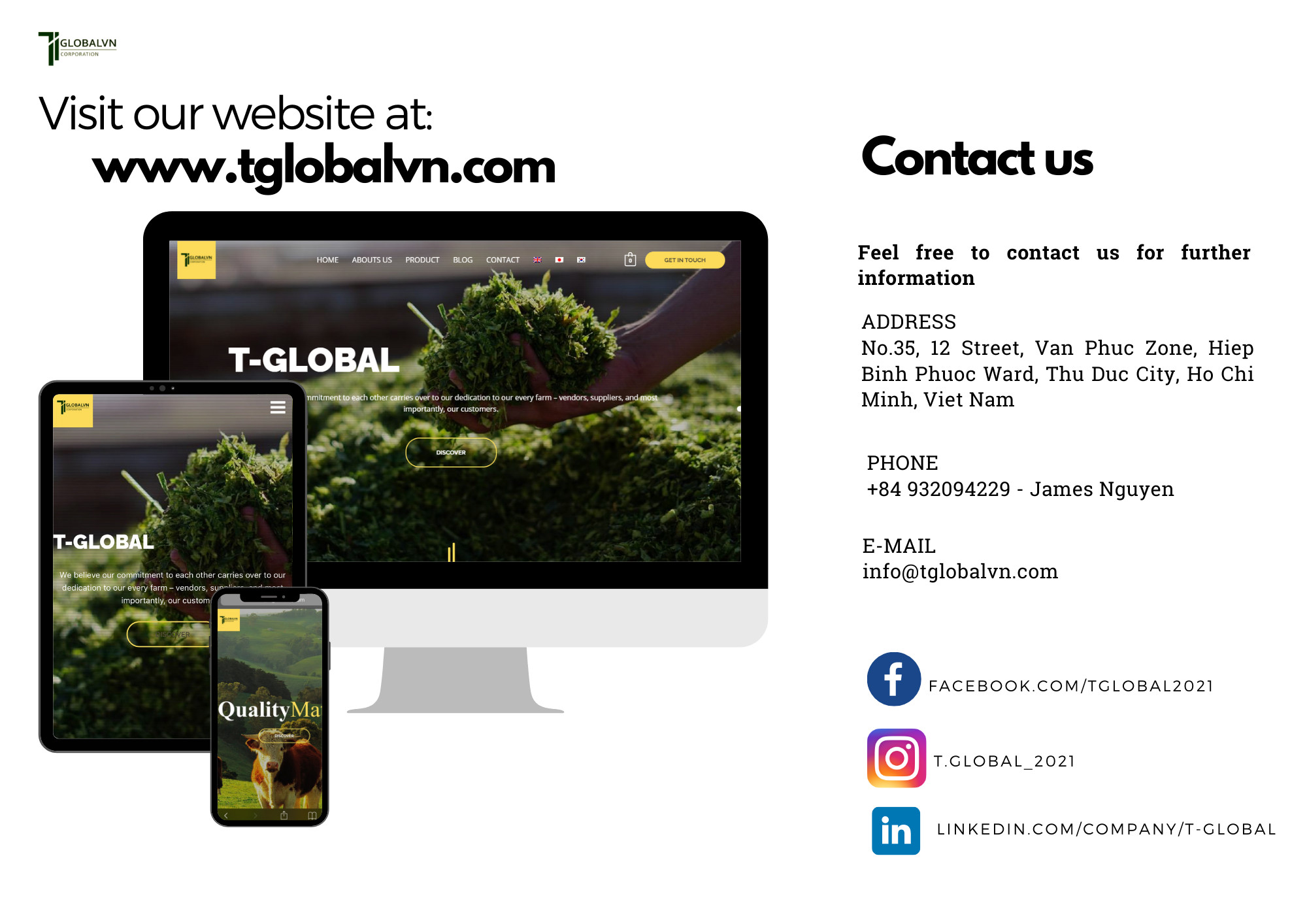

T-Global manufacture high-quality Cassava Bagasse from Viet Nam.

Visit us at: www.tglobalvn.com